|

November 15, 2019 Implantable Medical Device Preparation - Cleaning and Etching with Nitric Acid / Hydrofluoric Acid Mixtures

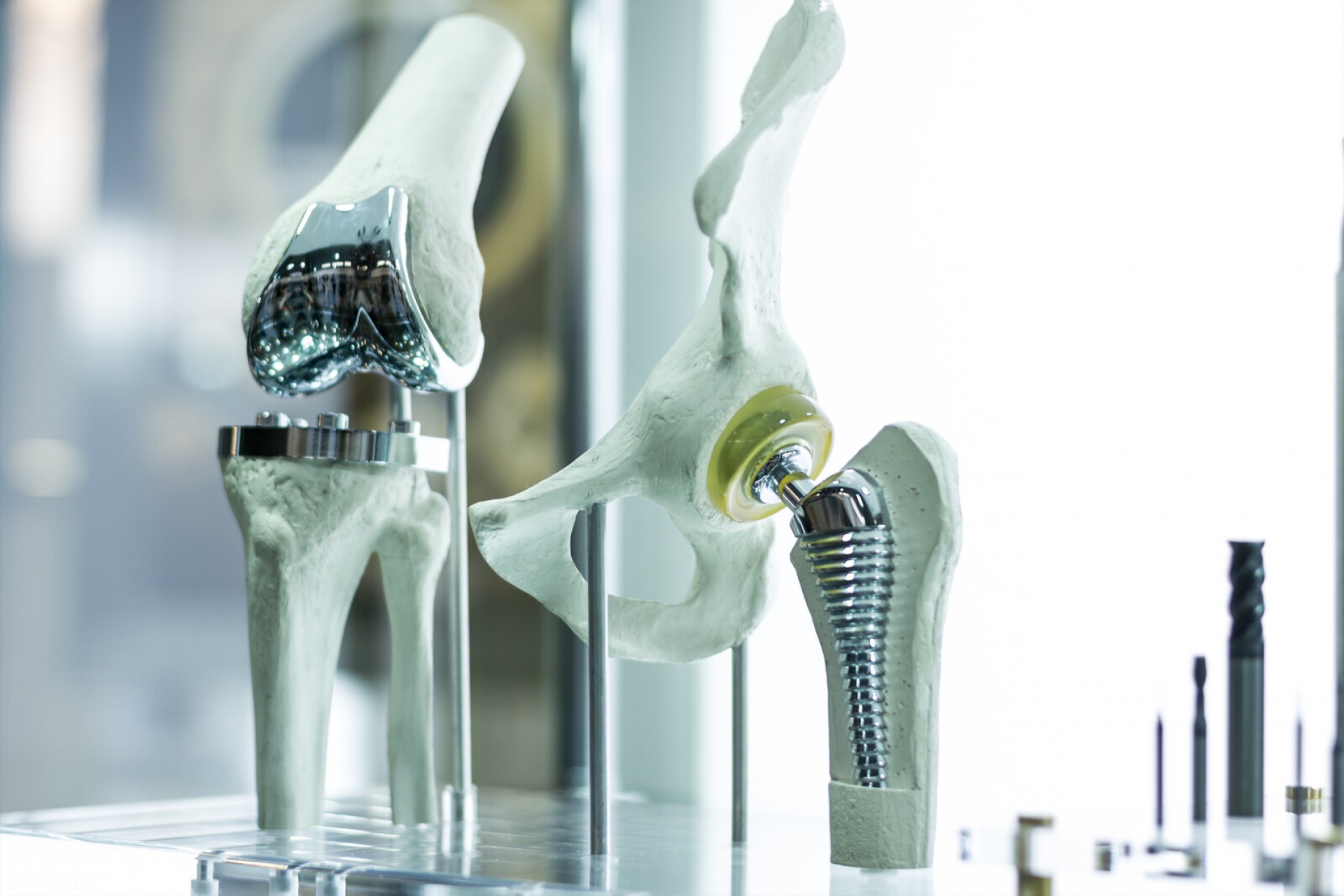

Achieving 100 percent adhesion of bioactive coatings is imperative, as this is what allows the device to properly attach to bone or living tissue and prevent the body from rejecting an implant. The method for achieving a clean, perfectly smooth surface involves the use of strong etchants. NuGenTec’s line of hydrofluoric acid (HF) / nitric acid mixtures is designed specifically to create the uniform and clean surface required for implantable medical devices.

Why Hydrofluoric acid and Nitric Acid Mixtures are Perfect for Implantable Medical Device Etching

Etching is a process wherein an acid is used to cut away the outer layer of a metal - leaving a uniform, smooth surface. Nitric and hydrofluoric acids create prepare implantable medical devices with excellent efficiency due to their ability to both cut down the irregular surfaces of the metal (etching) and form compounds with the stray metal ions (chelation). Implantable devices are often made from titanium, stainless steel or Nitinol (NiTi) and must be etched to improve the surface texture for proper coating adhesion.

Mixtures containing hydrofluoric and nitric acids are used to clean and etch the surface of various implantable medical devices including:

- Stents

- Bone plates

- Dental implants

- Pins and screws

- Rods and bars

- Spinal fusion cages

To learn more about hydrofluoric and nitric acid mixtures, click here.

NuGenTec: Redefining Chemistry

If you are seeking healthier, more environmentally responsible, and less costly alternatives for your industrial processes, contact NuGenTec today.

|