October 31, 2019 NuKlean Reflow Oven Cleaner Keeps Reflow Ovens Functioning Like New

Over repeated use, reflow ovens build up residues that are tenacious and interfere with the oven temperature profile consistency and overall performance. Maintaining a clean reflow oven is easy with NuGenTec’s specially formulated NuKlean Reflow Oven Cleaner.

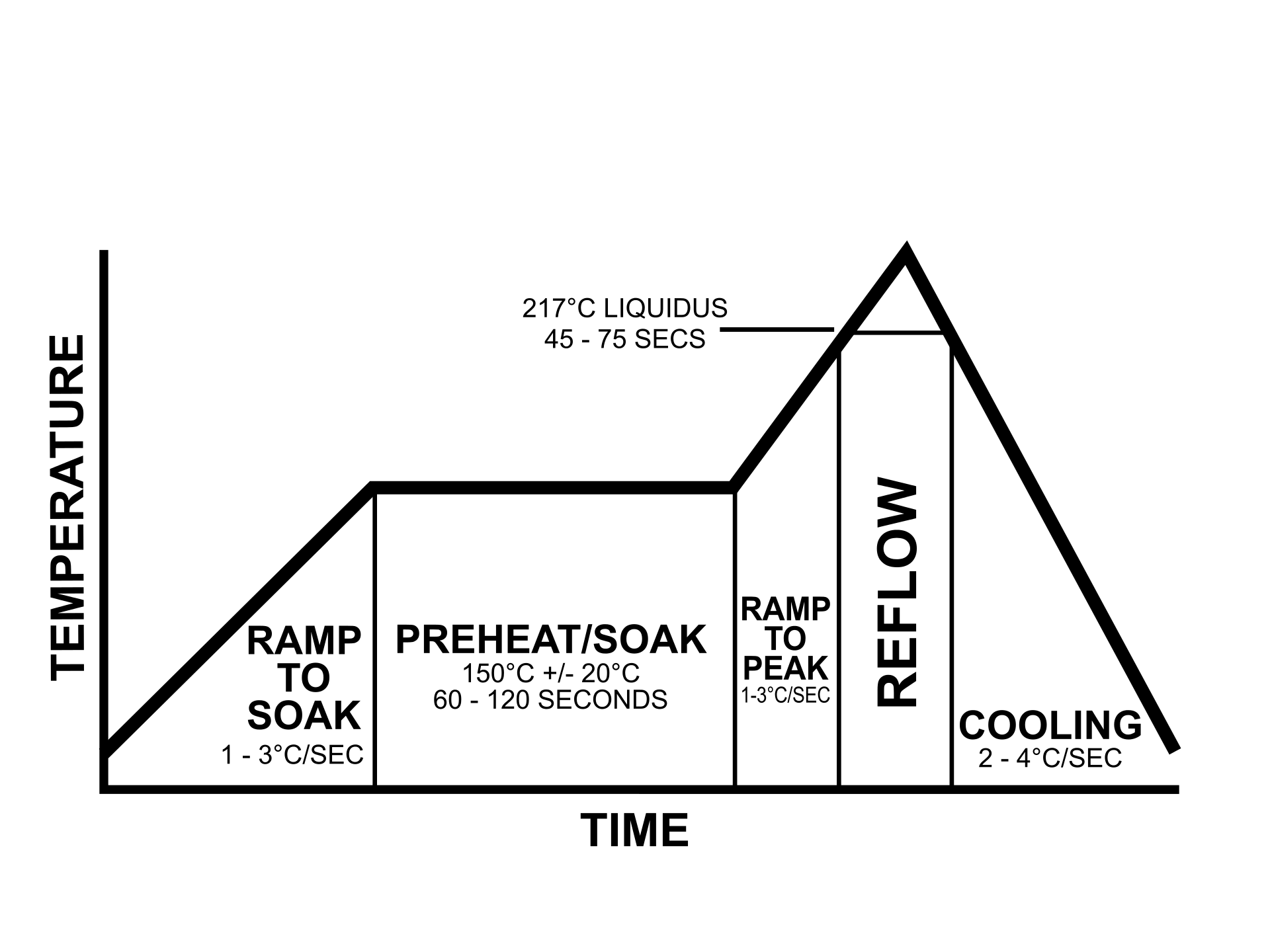

Why is Reflow Oven Cleaning Important?Maintaining an optimal temperature profile is key to the efficacy of the reflow oven. An example of a thermal profile for reflow soldering is shown on the right. As the oven is used, some of the flux and solder resist will evaporate and recondense on components of the reflow oven. When these residues become burnt onto the machine surfaces, they become difficult to remove and interfere with the thermal profile. When the thermal profile is too far from its original state, the reflow oven will either need to be replaced or cleaned. Cleaning the reflow oven is easy with NuKlean Reflow Oven Cleaner.How Does NuKlean Reflow Oven Cleaner Work?NuKlean Reflow Oven Cleaner is specifically formulated to remove the build-up from components of soldering machines and circuit boards. NuKlean Reflow Oven Cleaner removes tenacious burnt-on flux residues from all reflow and wave soldering machine surfaces including pllets, baffles, heating elements, clamps, chains, drive gears and housings. NuKlean Reflow Oven Cleaner is also highly effective at removing fluxes, no-clean fluxes, pastes, organic residues, adhesives, greases and oils from SMT and BGA circuit boards, connectors and components.NuGenTec: Redefining ChemistryIf you are seeking healthier, more environmentally responsible, and less costly alternatives for your industrial processes, contact NuGenTec today. Click here to learn more about NuKlean Reflow Oven Cleaner. |

High Performance Specialty Chemicals & Services

Contact Us